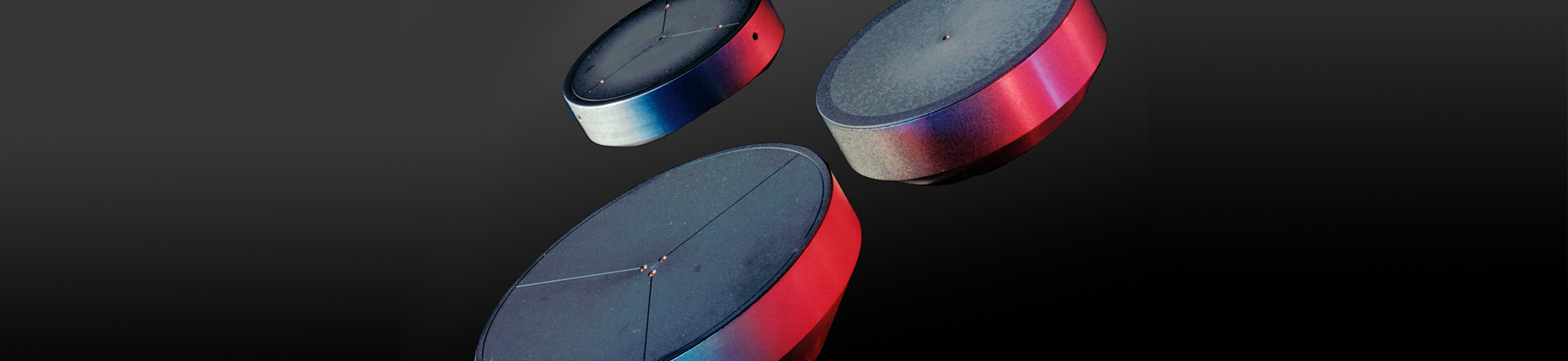

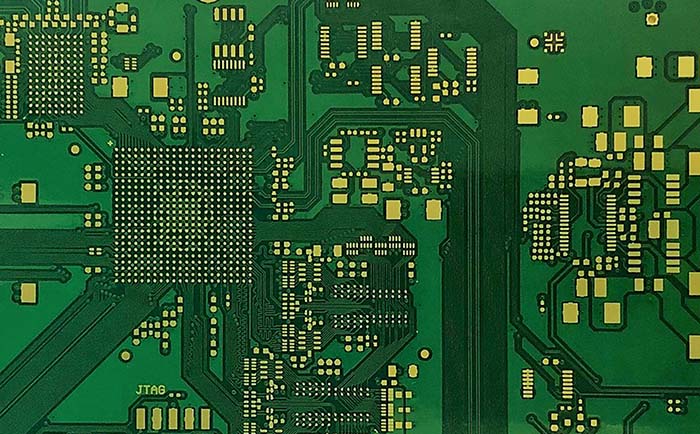

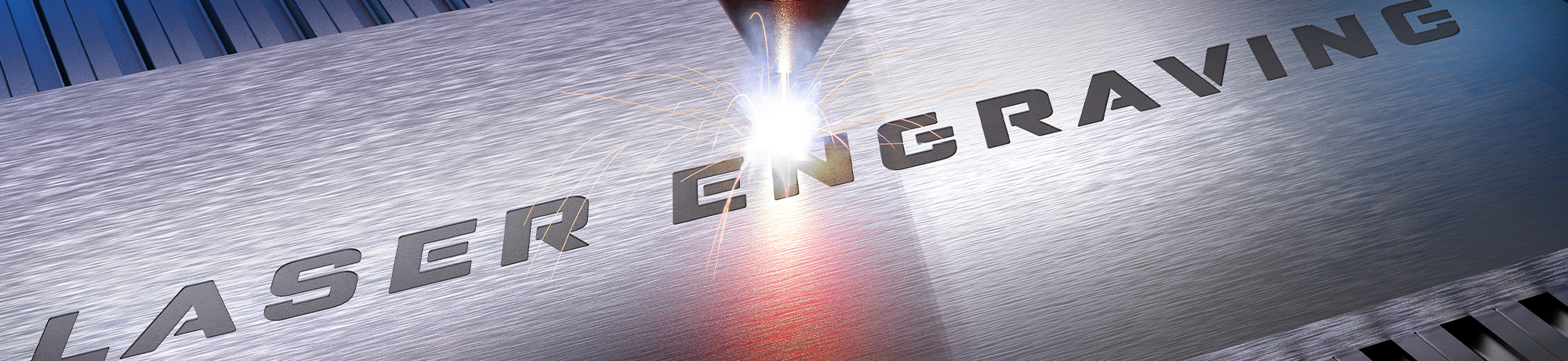

The universal laser marking system LAS 28 XL from Systemtechnik Hölzer GmbH can be used for a very wide range of marking applications. With the integrated fiber laser you can mark almost all materials such as steel, carbide, aluminum and plastics.

Depending on the requirements, the system can be equipped with a 20, 30 or 50 watt fiber laser. For permanent marking, the use of the laser is necessary in many industries.

With the powerful laser software, texts, numbers, 2D codes, QR codes and logos can be realized with just a few clicks without extensive programming knowledge. Serial and article numbers are automatically incremented by the software after prior setting. In addition, the software can read data (variable information such as drawing numbers, project designations, etc.) from existing tables and automatically transfer them to predefined areas. The use of a hand scanner is also possible.

The standard equipment includes a laptop incl. holder with Windows operating system and laser software. Optionally, the laser model LAS 28 XL can be equipped with a rotary axis (3-jaw chuck) for marking cylindrical parts. Further options, such as lateral extension arms for marking long parts, movable Z-axis, drawer systems, etc., can be realized.

The LAS 28 XLe laser marking system from Systemtechnik Hölzer GmbH is a versatile, high-performance marking system for industrial applications. It is suitable for precise, permanent marking of a wide range of materials, including metals such as steel, aluminum, and carbide, as well as plastics. The integration of a fiber laser ensures high marking quality with low maintenance requirements.

The system can be configured with fiber lasers in the 20 W, 30 W, or 50 W power classes and can thus be optimally adapted to different requirements in terms of material type, marking depth, and cycle time. In many industrial sectors, the use of this technology is indispensable due to the durability and abrasion resistance of the markings.

The supplied laser software enables the creation and positioning of content such as text, numbering, 2D codes (e.g., DataMatrix), QR codes, and logos. The automatic serial number logic allows consecutive number sequences to be generated without manual intervention. In addition, the software allows external data sources (e.g., Excel tables) to be imported and processed for variable content such as drawing numbers or project names. A handheld scanner can be connected for data acquisition as an option.

The LAS 28 XLe comes standard with an integrated industrial PC (Windows-based) and the laser software fully installed. Various options are available to expand functionality, including a rotating axis (3-jaw chuck) for marking cylindrical components, side arms for processing long parts, a movable Z-axis, and modular drawer systems for parts feeding.