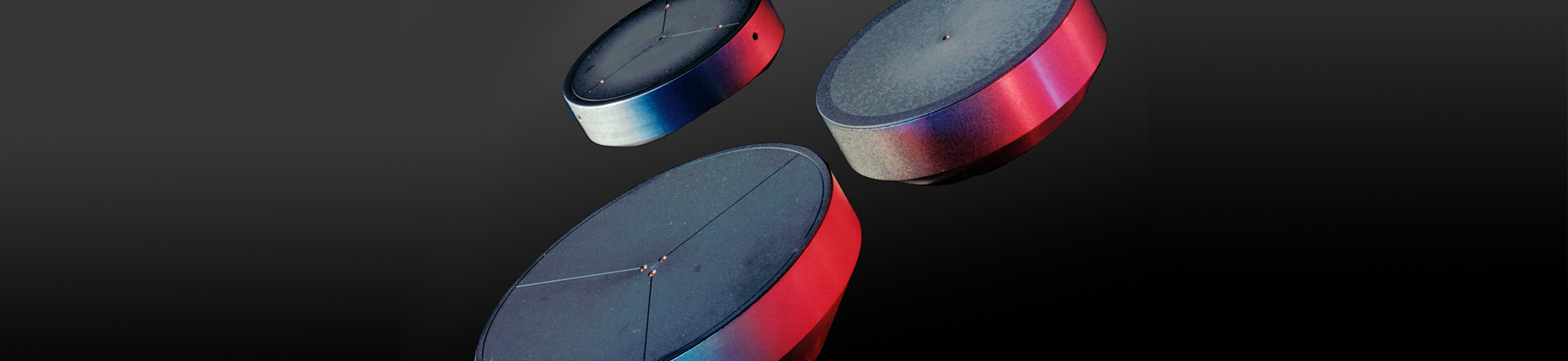

Highest Precision with minimal

resistance- Air bearings made in Germany

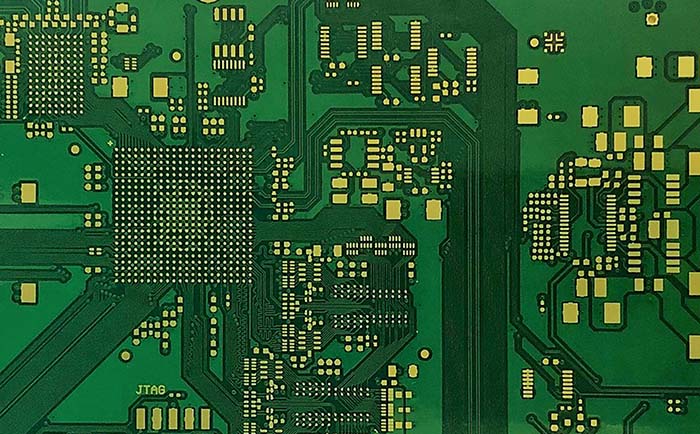

Separation of PCB´s

- neatly and efficiently integrated

Family led for over 30 years

Quality and Commitment in the Team

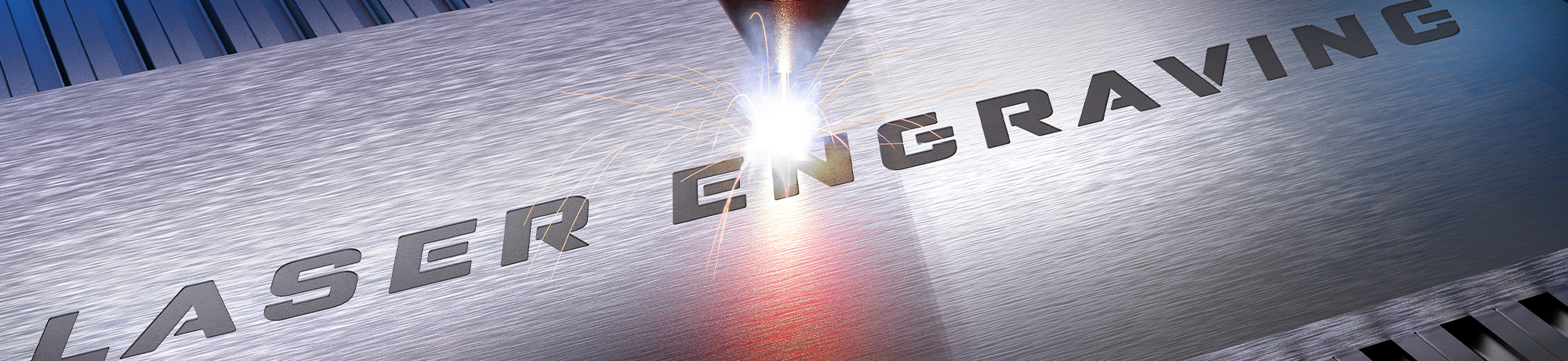

Shaping the future of the Industry

4.0 with Laser Technology