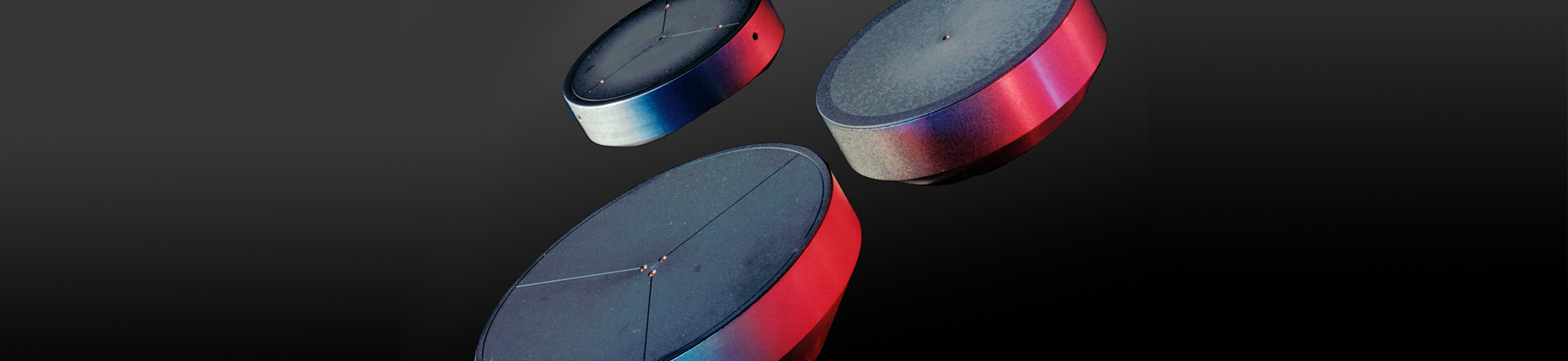

To meet the high accuracy requirements of positioning tasks, the use of nozzle air bearings and surface air bearings for linear and rotary applications has become indispensable in industry. We combine your technology with our know-how.

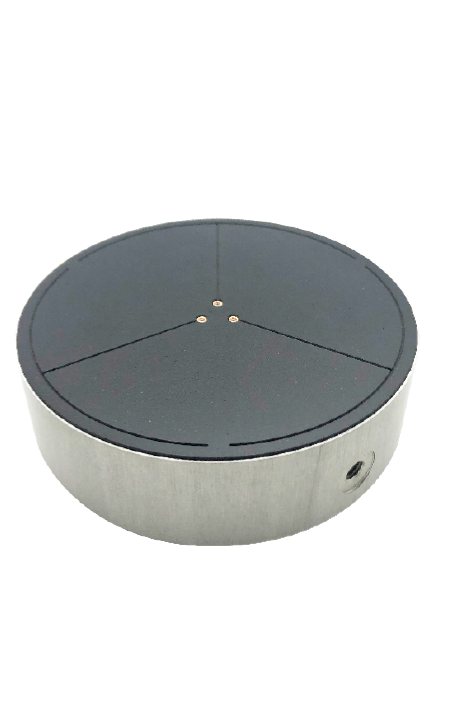

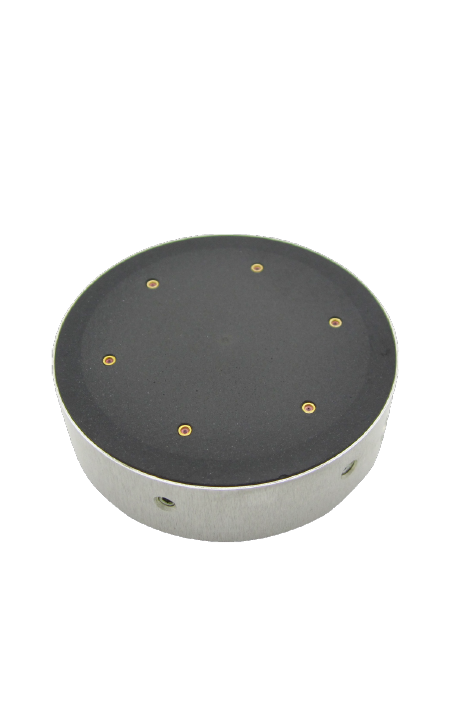

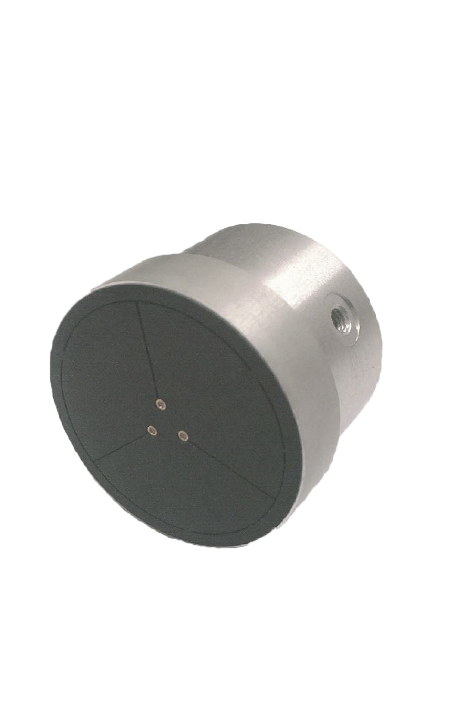

Systemtechnik Hölzer GmbH supplies customized air bearing solutions made of metal, plastics and composite materials for all applications. The spectrum includes all common air bearing technologies - nozzle air bearings with varying numbers of nozzles for linear and rotary applications in the form of support, guide or compensating bearings, as well as transport bearings made of sintered material for non-contact handling of sensitive materials, such as displays and photovoltaics.

Hovering on 4 μm air tons

In connection with ever higher accuracy requirements for positioning tasks, the use of granite- or steel-based air bearing guides has steadily spread in recent years. We combine your technology with our know-how.

Precision air bearings - technology of the future

With a much higher precision than e.g. rolling bearing based linear guides, the interaction of air bearing and linear motor technology offers the perfect solution.

1. efficiency

The efficiency/utilization factor of the Hölzer bearing system technology is high due to its design, as the maximum bearing pressure can build up over a very large area of the bearing face before it is released to atmospheric pressure.

2. stiffness

More important than the efficiency in terms of load carrying capacity of an air bearing is its stiffness, which is defined by the ratio of load change to flight height change. The basic stiffness of an air bearing also depends on its design. Air bearings made of sintered material are therefore in principle inferior to fully developed jet air bearings. A constant stiffness rate, which can suffer due to variations in nozzle diameter, other things being equal, is achieved at SH by using a diamond in the bearing nozzles, among other things. In particular, the ring-groove bearings, which have three supporting segments that achieve the anti-tilt effect of a three-legged chair, are characterized by a surface with very high flatness, since Systemtechnik Hölzer has a great deal of expertise in the field of lapping.

3. optimal tuning

Systemtechnik Hölzer bearings are characterized by an optimal tuning of the corresponding determinants - size of the bearing cavity - optimal air gap (interaction of feed pressure, nozzle cross-section, load capacity for the corresponding requirements). In principle, any bearing can become unstable by changing these parameters. SH offers the possibility, through adjustable bearings, to compensate for the manufacturing tolerances of the mounted body in order to achieve a constant pressure across all air bearings, which increases the stiffness of the overall system.

4. operating costs

The combination of the above advantages of SH air bearings with the comparatively low operating costs, especially in terms of air consumption compared to sintered material based air bearings, make SH air bearings the first choice for economically fulfilling high precision positioning tasks.